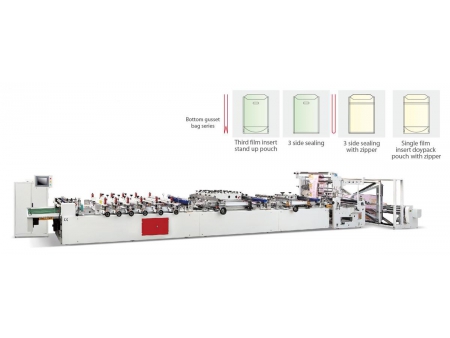

Zipper Bag Making Machine (Thermal Bonding), Bag Making Machine with Zipper Attachment

XINDA zipper bag making machines are able to make all types of zipper,reclosable,slider bags through thermal bonding or attaching the zipper onto the flat film. Our bag making machine settles many difficulties and limits that the traditional way encountered to make the zipper bags, such as multicolored printing requirement . The sizes of bags should be limited by the die heads, etc.

- Feed out the flat film by photoelectric deviation-rectifying unwinder

- Edge folding the single layer film to double layer film by magnetic powder tension control (optional parts)

- Bottom folding (makes a bottom gusset if required by customer)

- Zipper feed in device (can be a dependent stand or fixed on the machine)

- Attachment part (used to thermal bond the zipper onto the film)

- Spare parts: Ultrasonic device, photoelectric tracking device, puncher, etc.

- Cutting and sealing part (converts the zipper film into bags)

- Work table (regularly collects the zipper bag)

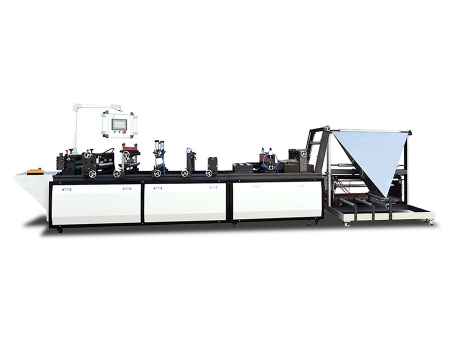

Configuration

Our zipper bag making machinery features a YASKAWA Servo motor driven, efficient mechanical structure. It offers a user-friendly control panel and is easy to understand and operate. The digital controller adjusts the production length precisely, producing less wastage. The zipper bag making machine offers an excellent design and precise assembly. It is durable and easy to maintain and replace parts.

Our zipper bag making machine is easy to operate and offers pleasant cutting and sealing with high firmness and no scratching. The machine is equipped with an exact time printing tracing control for accurate registration, so when printing error occurs machine will stop automatically. The zipper bag making machine can be equipped with an auto slider-insert device and hanger attachment device, etc., according to the customer’s special requirement.