Light Steel Villas

Request a Quote

Prefabricated Construction

We offer custom solutions for your prefab houses with light steel structures

Do you dream of a beautiful, durable, eco-friendly, and cost-effective home?

Our light steel villas are built with aerospace-grade galvalume steel, offering seismic resistance up to magnitude 7 and wind resistance up to level 9. You can move in just 30 days after construction begins! Compared to traditional buildings, our villas reduce costs by 40% and improve thermal insulation performance by 60%, this is what the future of housing looks like!

Light Steel Villa Drawing

- Solar energy system

- Air vent

- Roofing tiles

- Roof frame structure

- Outer wall panels

- Wall framing system

- Energy-efficient windows

- Floor structure

- Electrically operated garage door

- Decorative brick façade

- PVC guard rail

Light Steel Villa Solution

Light steel villa design

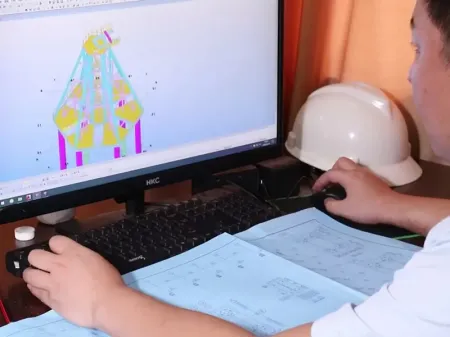

Production of light steel villa components

On-site installation or remote installation guidance

Core Materials and Component List

Main Structure

- G550 galvalume steel studs (thickness: 0.8–2.0 mm)

- High-strength bolt connectors (Grade 10.8)

- Fiberglass

- Span

- Plasterboard

- Truss

- Metal Tile

- Span

Enclosure System

- OSB structural panels (9–15 mm)

- Fiberglass insulation layer (100–150 mm)

- Waterproof breathable membrane (DuPont™ Tyvek® or equivalent)

Extruded polystyrene (XPS) board

Calcium silicate board

Oriented strand board (OSB)

Light steel keel

Cement board

Fiberglass and rock wool insulation

Exterior Wall System

- Metal embossed panels (50-year warranty)

- Real stone-texture paint finish (optional)

- Wood grain aluminum panels (antique style)

Roof System

- Asphalt shingles (30-year lifespan)

- Metal roofing tiles (hail-resistant)

- Stud

- Plasterboard

- OSB

- Vapor Barrier Paper

- XPS

- Mortar with Mesh

- Wall Tile

- Fiberglass

Game-Changing Advantages

- Cost-Effective & Worry-Free Overall cost savings of 35–40%

- Healthy & Eco-Friendly Zero formaldehyde; 95% of materials are recyclable

- Exceptionally Strong Earthquake-resistant (up to magnitude 8), wind-resistant (up to level 12)

- Comfortable All Year Round 3× better insulation than traditional brick-concrete structures

- Fire & Moisture Resistant Fire resistance up to 2 hours, mold and pest resistant

Project Cases

3-Storey Steel Structure Residential Building in Netherlands

- Area: 280 square meters (single storey 100m²)

- Weight: 60 tons

- Wind speed: 28 m/s (≈100 km/h)

- Seismic resistance: Grade 7

- Floor live load: 2.0 kN/m² (living area)

- Roof live load: 0.6 kN/m² (snow load area)

- Surface finish: painted

172m² Prefab Light Steel Gauge House in Romania

- Area: 172 square meters

- Steel building size (L×W×H): 11.2×16.4×3m

- Wind speed: 110 km/h

- Location: Romania

- Finished date: Dec-2021

Steel Frame Prefab Country House

- Area: 515 square meters (2 or 3 storey)

- Weight: 45~65 tons

- Wind speed: 25~30 m/s (≈90~108 km/h)

- Seismic resistance: Grade 7 (0.10g)

- Floor live load: 2.0 kN/m² (living area)

- Stair/balcony load: 3.5 kN/m²

- Roof live load: 0.5 kN/m²

- Surface finish: painted

How many stories can a light steel villa have? What is the maximum span?

How many stories can a light steel villa have? What is the maximum span?

Up to 6 stories; maximum span is 12 meters.

What are the advantages of light steel villas compared to traditional concrete buildings?

What are the advantages of light steel villas compared to traditional concrete buildings?

- Light steel components are highly standardized, produced in factories and assembled on-site, cutting construction time by 40% compared to concrete buildings.

- Thinner walls and flexible structure—wall thickness is about half that of traditional walls, increasing usable space by around 5%.

- Use of efficient insulation materials such as fiberglass and foamed concrete with tightly sealed air pockets offers superior insulation and soundproofing.

- Integrated wall casting combined with mesh-form skin effect delivers high seismic resistance and crack prevention.

- 95% of building materials are recyclable, meeting green building standards.