ER 4047 (ALSi12) Aluminium Welding Wire

Request a Quote

Welding Consumables

Aluminium-silicon filler metal for MIG and TIG welding of aluminium-silicon alloys

- Chemical Designation: ALSi12

- Standard: AWS A5.10, GB/T10858-2023

Chemical Composition (%)

| Si | Fe | Cu | Mn | Mg | Zn | Al | Be | Others | |

| Each | Total | ||||||||

| 11.0-13.0 | ≤0.8 | ≤0.30 | ≤0.15 | ≤0.10 | ≤0.20 | Rest | ≤0.0003 | ≤0.05 | ≤0.15 |

Mechanical Properties

- Tensile Strength (MPa): ≥170

- Yield Strength (MPa): ≥80

- Elongation (%): ≥4

Features

- Contains 12% silicon, providing excellent fluidity during welding

- Lower melting temperature helps minimize distortion in thin materials

- Good for filling wide or irregular gaps and reducing the risk of hot cracking

Available Sizes

- Welding wire: 1.2/1.6/2.0/2.4/3.0/3.2/4.0/5.0/6.0mm

- Spool: D300 (9kg), D270 (7kg), D200 (2kg), D100 (0.5kg)

Applications

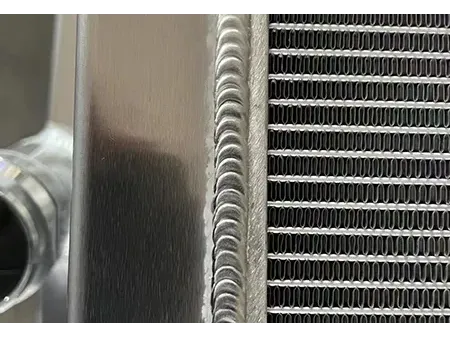

- Automotive aluminium radiator, intercooler, and heat exchanger welding

- Window frame assembly for aluminium passenger buses

- Bicycle frame fabrication

- General aluminium part repair and maintenance

Packaging

- MIG wire diameter: 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm

- Package: D300 (9kg/spool), D270 (7kg/spool)

- MIG wire diameter: 1.2mm, 1.6mm

- Package: drum D660 (100kg/drum)

- TIG wire diameter: 2.0mm, 2.4mm, 3.0mm, 3.2mm, 4.0mm, 5.0mm, 6.0mm

- Package: 1000mm length (10kg/box)

- TIG wire diameter: 1.6mm, 2.0mm, 2.4mm, 3.0mm, 3.2mm, 4.0mm, 5.0mm, 6.0mm

- Coil inner diameter: D450mm, D300mm

- Package: 10-17kg/coil

Recommended Welding Method

For optimal results, this type of welding wire is commonly used in brazing with an oxy-fuel torch. Pair it with 201 aluminium flux to enhance flow and bonding quality.